PRODUCTS

We strive to ensure end-to-end quality. We receive raw materials from large companies, process pig iron using cutting-edge technology, and deliver the product to customers efficiently and responsibly.

PROVIDING PIG

IRON TO THE

INDUSTRY WHEN

IT NEEDS IT.

Understanding the dynamics of our sector and the needs of our clients, we are fully prepared to deliver high-quality products when they are needed and how they are needed. Chemical quality control is carried out in our own laboratory, where systematic and periodic analyses are performed. This enables us to offer steel mills and foundries exceptional virgin metal, ensuring excellent performance in electric furnaces due to the high carbon content of our product.

QUALITY

Our day-to-day work brings together the best practices of our industry with cutting-edge technology to deliver a product of the highest quality and precision. We are always moving forward, seeking new paths and constantly improving our processes.

THE EXPERIENCE OF THOSE WHO KNOW TO GUARANTEE THE BEST PRODUCT AND SERVICE

We take pride in the quality of our products. Each step is meticulously monitored through careful analysis of the raw materials and the final product in our own laboratory during the blast furnace stage. Based on this evaluation, we classify the iron pig iron content.

Exact traceability is provided to our customers.

We can also accommodate other qualities and special grades upon request.

Analysis results can also be provided upon request. Once the pig iron is cast, it is either stored in our inventory or delivered directly to customers. We are also able to cater to other qualities and special grades upon request.

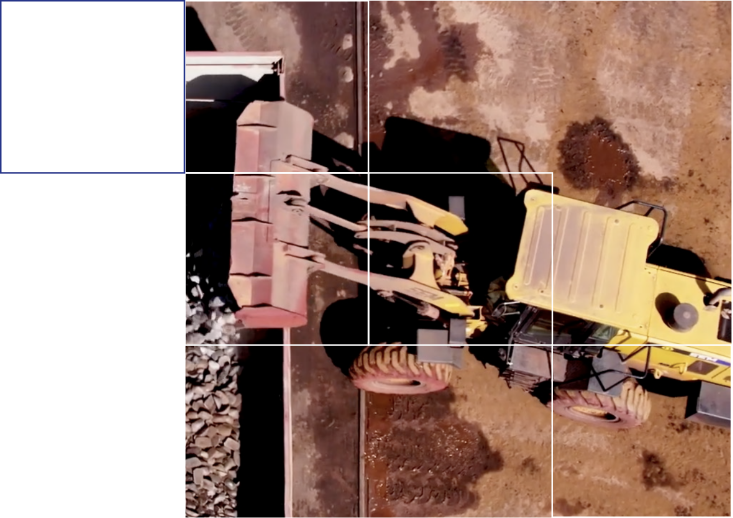

PROCESS

The blast furnace, known as the chemical reactor in the steel industry, is responsible for extracting pig iron from iron ore. They vary in size and are externally lined with metal, and internally with refractory material. Within our industrial facility, we have two blast furnaces from which our products are produced and delivered to our customers on time and to strict quality standards.

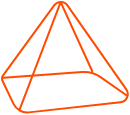

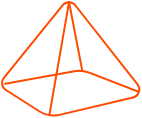

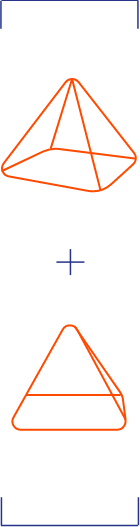

PHYSICAL CHARACTERISTICS

Shape and

weight

Our ingots come in a convenient pyramid shape, weighing approximately five kilograms. This design facilitates transportation and stacking.

Density

With a specific density of 3.5 tons/m³, it allows for the compaction of scrap in the blast furnace, leading to increased productivity in the steel mill.

Chemical

characteristics

Our pig iron reaches an impressive 95% Fe content, free from gangue, and with minimal sulfur and phosphorus impurities. This contributes to the superior quality demanded by steel mills and foundries.

TYPES OF

PIG IRON

Basic Pig Iron (Steel Mills)

Used in electric arc furnaces for the production of flat steels (used in industries such as automotive and household appliances) and long steels for the construction industry and other industries.

Composition:

C: 3.50% - 4.50%

Mn: Maximum 1.00%

P: Maximum 0.12%

S: Maximum 0.05%

Grey Cast Iron (Foundries)

Also known as hematite pig iron, this variety is primarily used in the manufacture of gray iron castings in cupola furnaces or electric furnaces. Foundries rely on it for producing machine components and automotive parts like bushings, pulleys, rings, tables, bases, counterweights, flanges, couplings, clutch discs, brake drums, among others.

Composition:

C: 3.50% - 4.50%

Mn: 0.50% - 1.00%

P: Maximum 0.12%

S: Maximum 0.05%

Semi-Nodular and Nodular T5 Pig Iron

Also known as High-Purity Pig Iron (HPPI) and called spheroidal graphite, they have low manganese, phosphorus, and sulfur contents. Mainly used in the manufacture of ductile materials for special parts in the automotive and wind energy industries, and more.

Semi-Nodular

Composition

C: 3.50% - 4.50%

Mn: Maximum 1.00%

P: Maximum 0.10%

S: Maximum 0.03%

Nodular T5

Composition

C: 3.50% - 4.50%

Mn: Maximum 0.05%

P: Maximum 0.05%

S: Maximum 0.03%